Vacuum heat treatment through Hardening,

Annealing, Stress Relief & Ageing

Heat treatment is a way of heating and cooling a metal or alloy so as to impart the desired qualities into the component, to improve its performance and longevity.

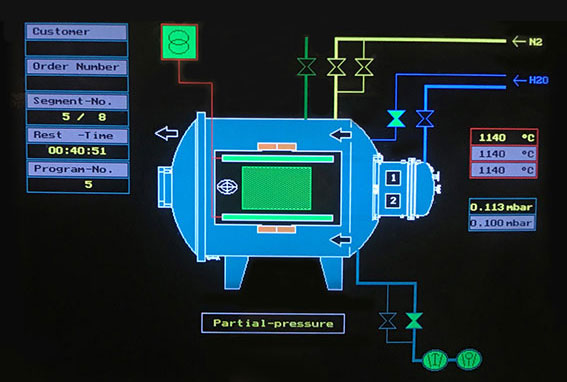

By using a vacuum, air and other residual contaminating gases are evacuated from the chamber.

Vacuum heat treatment is environmentally friendly as no salt baths or pollutants are used.

The parts are loaded into special baskets, using our bespoke fixturing from knowledge built up over many years, which helps to stabilise the components whilst they are being treated. The work is then placed in the furnace and pumped down, resulting in a vacuum. It is uniformly heated to the required temperature, soaked then cooled rapidly in argon, nitrogen or oil, whilst still in the furnace chamber. This reduces surface oxidisation. The parts are then tempered to the required hardness. At higher tempering temperatures, a surface greyness may appear which is purely superficial. Treated items suffer less distortion and on completion the components require less post-treatment finishing and cleaning, compared to other methods of heat treatment. This is a cost benefit, as they can be sent straight out for grinding or electroplating if necessary, often eliminating pre-cleaning.

Due to the precise control of temperature, time and quenching, accurate repeatability of the process is achieved.

We offer total commitment to providing the latest and best performance available from vacuum heat treatment through honesty, integrity, investment and meticulous attention to detail.

ADVANTAGES

Increased component life

• Achieved from accuracy and appropriateness of hardness values

• Improved fatigue properties

Quality control

• Personal approach and individual service enables discrepancies in materials or components to be identified

• Greater consistency and repeatability

Cleanliness

• Superior surface finish, with nil corrosion

Environmental and safety issues

• Environmentally friendly as no salt baths or pollutants are used

Repeatable results

• From fully traceable and controlled treatments

Speed

• Reduced need for post-treatment finishing

• Effective communication improves turnaround

Reduced costs

• Less distortion and improved cleanliness

Less waste

• Due to careful handling and precise controls

Reduced distortion

• Results in less grinding or machining required post treatment

Call Us:

Call Us:

Message Us:

Message Us: